Magnetfinish GmbH

Brünigstrasse 64

6074 Giswil

Switzerland

+41 79 549 57 73

thiel@magnetfinish.com

EMO Hannover 2025

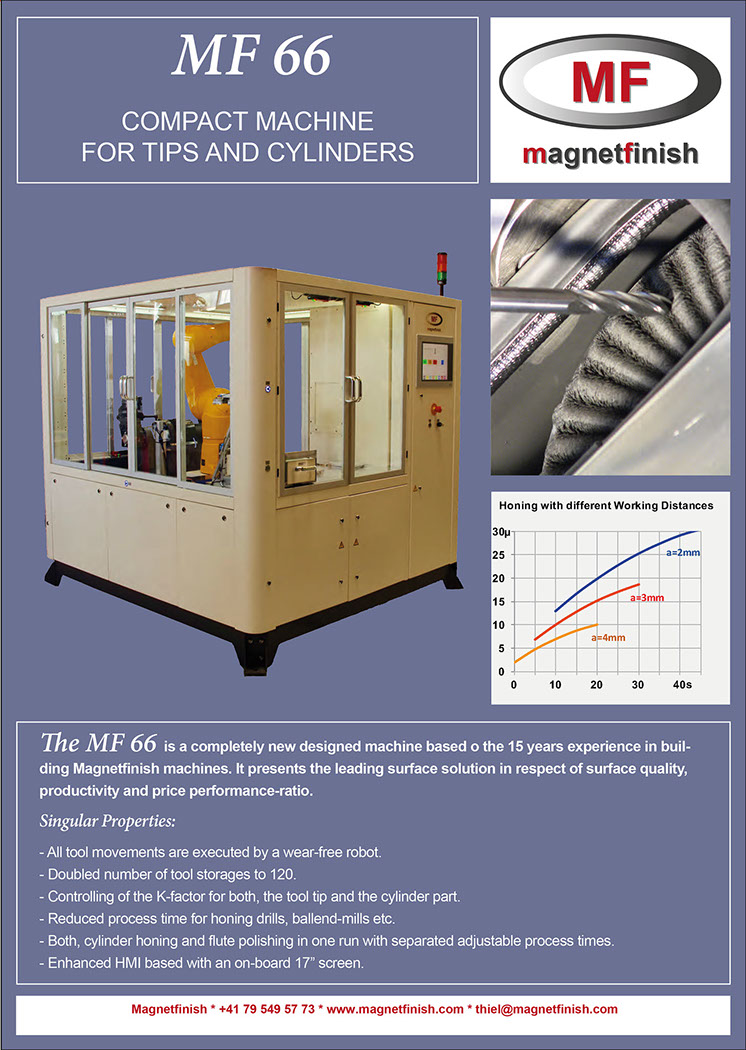

We exhibit our latest

machine generation at the booth of

our long-time partner

Wick AG Hall 11 - E 89

Copyright © 2025 Magnetfinish GmbH, Sandra Reichmann, all rights reserved

GENERAL BUSINESS TERMS